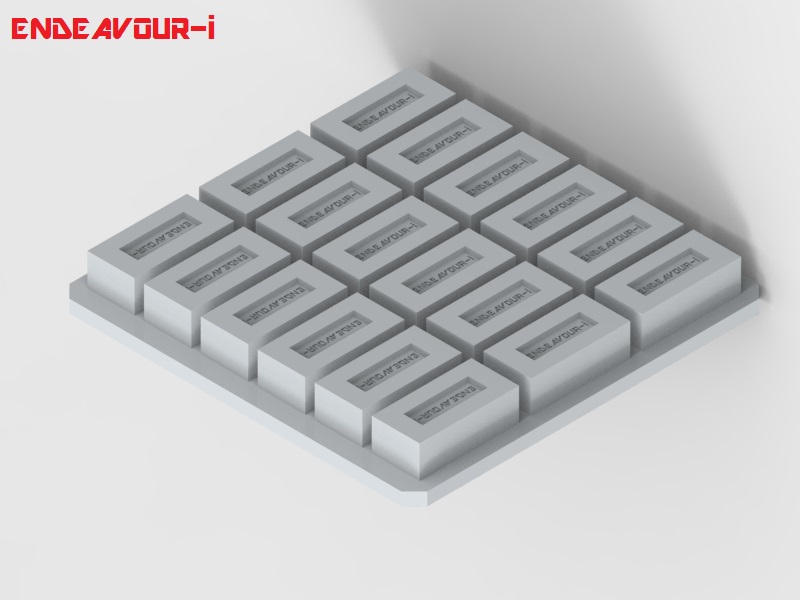

To make high-quality fly ash bricks, it’s important to follow a precise manufacturing process and use the right mix of materials. Here are some key guidelines: Material Proportions: A common mix ratio is 55-60% fly ash, 30-32 % Sand OR Stone Dust & 8-10% cement (by weight). Ensure the fly ash is fine and free from carbon particles to improve the brick’s quality. Mixing: Use efficient mixing tools like a pan mixer to achieve a homogenous mixture. Pan Mixer is likely to have Lump Crushing Rollers to Crush the Lumps formed due to Moisture in Raw Materials. The materials should be blended thoroughly to ensure consistency in the bricks. Molding: Hydraulic Operated Bricks/Blocks Forming Machine is used to Form the Bricks/Blocks. The Mixture is then pressed into brick molds. There are Two Type of Method for Bricks Molding. If you are using Fly Ash as Main Raw Material, then High Pressure Type Bricks Molding Machine is more suitable. The pressure should be adequate to form compact bricks. If you are u sing Fly Ash in Minor & Sand Or Stone Dust as Major in Mix Design, Then Vibro Compacting Bricks & Blocks Making Machine is More suitable which forms Bricks or Blocks by High Vibration instead of High Pressure. Select Machine Type as per Raw Materials Availability nearby your Site. Drying and Curing: Allow the bricks to dry under the sun or in a controlled environment. Curing is crucial for strength and durability. Bricks should be cured for at least 14 days. Quality Standards: Adhere to BIS standards for fly ash bricks to ensure quality and market value. Environmental Compliance: Follow local environmental guidelines for the use of fly ash in brick manufacturing. By maintaining these standards, you can produce fly ash bricks that are strong, durable, and have a low water absorption rate, making them suitable for various construction purposes. Please Contact us for more details: ENDEAVOUR INTELLIGENT EQUIPMENTS PRIVATE LIMITED Survey No: 1206, At: Motap, Ta: Becharaji, Dist: Mehsana, Modhera Road, Mehsana, Gujarat - 384410 E Mail: endeavourintelligent@gmail.com Website: www.endeavour-i.com Mobile: Mr. Dinesh K Suthar: +91-9427352508 Mr. Piyush K Suthar: +91-9737663977

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

2024-03-26T13:54:06

To make high-quality fly ash bricks, it’s important to follow a precise manufacturing process and use the right mix of materials. Here are some key guidelines: Material Proportions: A common mix ratio is 55-60% fly ash, 30-32 % Sand OR Stone Dust & 8-10% cement (by weight). Ensure the fly ash is fine and free from carbon particles to improve the brick’s quality. Mixing: Use efficient mixing tools like a pan mixer to achieve a homogenous mixture. Pan Mixer is likely to have Lump Crushing Rollers to Crush the Lumps formed due to Moisture in Raw Materials. The materials should be blended thoroughly to ensure consistency in the bricks. Molding: Hydraulic Operated Bricks/Blocks Forming Machine is used to Form the Bricks/Blocks. The Mixture is then pressed into brick molds. There are Two Type of Method for Bricks Molding. If you are using Fly Ash as Main Raw Material, then High Pressure Type Bricks Molding Machine is more suitable. The pressure should be adequate to form compact bricks. If you are u sing Fly Ash in Minor & Sand Or Stone Dust as Major in Mix Design, Then Vibro Compacting Bricks & Blocks Making Machine is More suitable which forms Bricks or Blocks by High Vibration instead of High Pressure. Select Machine Type as per Raw Materials Availability nearby your Site. Drying and Curing: Allow the bricks to dry under the sun or in a controlled environment. Curing is crucial for strength and durability. Bricks should be cured for at least 14 days. Quality Standards: Adhere to BIS standards for fly ash bricks to ensure quality and market value. Environmental Compliance: Follow local environmental guidelines for the use of fly ash in brick manufacturing. By maintaining these standards, you can produce fly ash bricks that are strong, durable, and have a low water absorption rate, making them suitable for various construction purposes. Please Contact us for more details: ENDEAVOUR INTELLIGENT EQUIPMENTS PRIVATE LIMITED Survey No: 1206, At: Motap, Ta: Becharaji, Dist: Mehsana, Modhera Road, Mehsana, Gujarat - 384410 E Mail: endeavourintelligent@gmail.com Website: www.endeavour-i.com Mobile: Mr. Dinesh K Suthar: +91-9427352508 Mr. Piyush K Suthar: +91-9737663977

2024-03-26T13:54:06

Keywords

- use

- sun

- Dist

- Site

- Motap

- Lumps

- Minor

- Major

- Mobile

- E Mail

- weight

- Method

- Drying

- Curing

- 14 days

- details

- Mehsana

- Gujarat

- strength

- Moisture

- Two Type

- Becharaji

- right mix

- pan mixer

- durability

- Mix Design

- consistency

- The Mixture

- brick molds

- 8-10% cement

- market value

- Modhera Road

- Machine Type

- BIS standards

- High Vibration

- key guidelines

- 55-60% fly ash

- compact bricks

- carbon particles

- common mix ratio

- Quality Standards

- Main Raw Material

- homogenous mixture

- Sand OR Stone Dust

- Mr. Piyush K Suthar

- Mr. Dinesh K Suthar

- brick manufacturing

- Material Proportions

- Lump Crushing Rollers

- Blocks Making Machine

- controlled environment

- efficient mixing tools

- Vibro Compacting Bricks

- Environmental Compliance

- low water absorption rate

- Raw Materials Availability

- high-quality fly ash bricks

- various construction purposes

- precise manufacturing process

- local environmental guidelines

- High Pressure Type Bricks Molding Machine

- Hydraulic Operated Bricks/Blocks Forming Machine

- ENDEAVOUR INTELLIGENT EQUIPMENTS PRIVATE LIMITED Survey

Submit Your Enquiry